Call: 08045476564

3-6mm Welded Mesh Panel Machine

3200000 INR/Set

Product Details:

- Product Type 3-6mm Welded Mesh Panel Machine

- Wire Material Low Carbon Steel, Galvanized Wire, Stainless Steel Wire

- Inlet Diameter 3-6 mm

- Outlet Diameter 3-6 mm

- Voltage 380 V / 415 V, 3 Phase, 50/60 Hz

- Power 8-12 kW

- Dimension (L*W*H) 6500 mm x 1800 mm x 2000 mm

- Click to View more

X

3-6mm Welded Mesh Panel Machine Price And Quantity

- 1 Set

- 3200000 INR/Set

- Up to 2500 mm

- Automatic

- 30-75 times/minute

- Galvanized, Black Annealed, Stainless Steel

- 50 mm x 50 mm to 300 mm x 300 mm (customizable)

- Integrated

- 0.6-0.8 MPa

- Heavy-duty steel structure

- Up to 24

- PLC Touch Screen Control

- Pre-cut or automatic

- Up to 120 m²/hour

3-6mm Welded Mesh Panel Machine Product Specifications

- Low Carbon Steel, Galvanized Wire, Stainless Steel Wire

- 3-6mm Welded Mesh Panel Machine

- Approx. 3200 kg

- 8-12 kW

- Blue & White, Customizable

- 6500 mm x 1800 mm x 2000 mm

- 3-6 mm

- Welding wire mesh panels for construction, fencing, industrial applications

- 380 V / 415 V, 3 Phase, 50/60 Hz

- 3-6 mm

- Up to 2500 mm

- Automatic

- 30-75 times/minute

- Galvanized, Black Annealed, Stainless Steel

- 50 mm x 50 mm to 300 mm x 300 mm (customizable)

- Integrated

- 0.6-0.8 MPa

- Heavy-duty steel structure

- Up to 24

- PLC Touch Screen Control

- Pre-cut or automatic

- Up to 120 m²/hour

3-6mm Welded Mesh Panel Machine Trade Information

- 10 Set Per Day

- 7 Days

Product Description

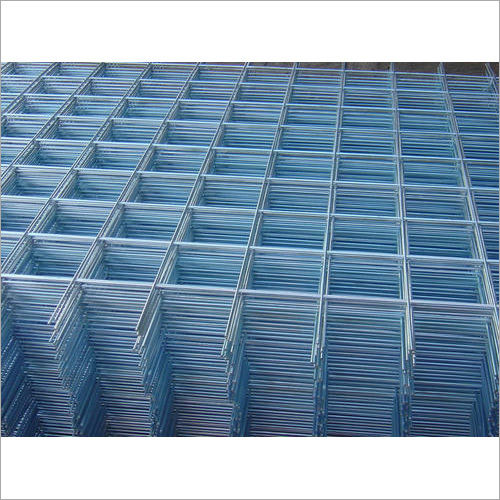

3-6mm Welded Mesh Panel Machine is an engineering apparatus used to make welded mesh panels of 3-6 mm diameters. The sophisticated machine automates the welding process thus ensuring that the panel dimensions are precise and uniform.# Its user friendly interface allows operators to vary mesh size and wire spacing. 3-6mm Welded Mesh Panel Machine is significant in construction and fencing industries where strong mesh structure is required. Its ability to be used a wide range of wire diameters makes it useful in producing a number of different applications thus ensuring high quality welding for mesh panel.

Advanced Automation and Control

Featuring a PLC touch screen control system, this welded mesh panel machine offers intuitive operation and precise parameter adjustments. With automatic line wire feeding and options for pre-cut or automatic cross wire feeding, it significantly reduces manual intervention, enhancing productivity and safety during mesh panel manufacturing.

Wide Customization for Versatile Applications

The machine supports mesh opening sizes from 50 mm x 50 mm up to 300 mm x 300 mm, catering to a diverse range of industrial, construction, and fencing requirements. Wire types include galvanized, low carbon steel, and stainless steel, providing broad compatibility and robust output suitable for various end uses.

Sturdy Construction and High Throughput

Built with a heavy-duty steel main frame and integrating up to 24 welding electrodes, this machine provides reliability and durability under continuous operation. Capable of producing up to 120 m of mesh panels per hour, it offers high throughput and efficiency, making it ideal for large-scale mesh panel production.

FAQs of 3-6mm Welded Mesh Panel Machine:

Q: How does the automatic wire feeding system work on this welded mesh panel machine?

A: The machines automatic wire feeding system automatically delivers line wires from coils while handling cross wires either via pre-cut lengths or an automated feeder. This minimizes manual handling and ensures precise alignment for consistent mesh welding results.Q: What types of wire materials are compatible with this mesh welding machine?

A: This machine is compatible with low carbon steel, galvanized wire, and stainless steel wire, within the diameter range of 3-6 mm. Its suitable for producing panels for various applications, including construction and industrial fencing.Q: Where can the 3-6mm welded mesh panel machine be used?

A: This machine is ideal for factories involved in construction mesh, fencing panels, and industrial mesh manufacturing. Its versatility allows installation in production facilities worldwide, particularly where customized mesh size and high productivity are required.Q: When is the integrated wire straightening feature most beneficial?

A: Integrated wire straightening is particularly beneficial when using coiled wires for line feeding, as it ensures the wires are perfectly straight before welding. This results in uniform mesh panels and reduces the risk of production defects.Q: What is the process for adjusting mesh sizes on this machine?

A: Mesh opening sizes can be adjusted through the PLC touchscreen interface, enabling users to specify both line and cross wire pitch according to the desired panel dimensions (from 5050 mm up to 300300 mm).Q: What are the main advantages of PLC touchscreen control on this panel welding machine?

A: The PLC touchscreen facilitates easy parameter input, quick recipe changeovers, real-time monitoring, and rapid troubleshooting, improving operational efficiency and reducing downtime during production runs.Q: What are the benefits of using this machine for large-scale mesh panel production?

A: With a welding speed of 30-75 times/minute, high electrode count, and a production capacity up to 120 m/hour, this machine enables efficient, consistent, and high-output manufacturing of welded mesh panels suited to demanding applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry