Call: 08045476564

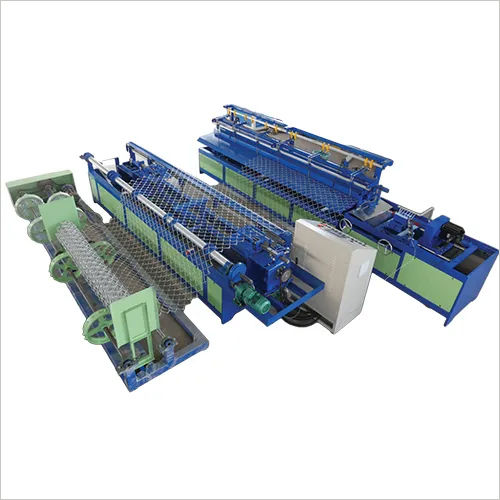

Best Automatic Chain Link Fence Machine

1125000 INR/Set

Product Details:

- Shape Rectangular Base, Woven Output

- Torque High torque motorized

- Phase Three Phase

- Diameter 1.8 - 4.0 mm

- Product Type Automatic Chain Link Fence Machine

- General Use Chain link fence and mesh production

- Material Galvanized Iron/Steel Wire

- Click to View more

X

Best Automatic Chain Link Fence Machine Price And Quantity

- 1125000 INR/Set

- 1 Set

- Emergency stop, Overload protection

- Multi-language interface

- 70-120 m/h

- Available on request

- 25 x 25 mm ~ 100 x 100 mm

- Automatic lubrication system

- 5C - 40C

- 5.5 kW

- Automatic feeding with tension adjustment

- Knuckled and twisted edge

- Standard export wooden case

- 1-4 m (adjustable)

- 75 dB

Best Automatic Chain Link Fence Machine Product Specifications

- Three Phase

- High torque motorized

- Fully automatic operation

- PLC Control

- Blue & White

- Galvanized Iron/Steel Wire

- Anti-corrosive painted

- 1.8 - 4.0 mm

- In-line quality inspection

- Rectangular Base, Woven Output

- Chain link fence and mesh production

- 2200 kg

- Double Wire Automatic Fence Machine

- Yes

- High speed, Low Noise, Auto edge locking, Continuous Feeding

- Mechanical Drawing Provided

- 380V/220V, 50/60 Hz

- Yes

- 2 mm

- Automatic Chain Link Fence Machine

- 120-180 m/hour

- 6800 x 1430 x 1800 mm

- Emergency stop, Overload protection

- Multi-language interface

- 70-120 m/h

- Available on request

- 25 x 25 mm ~ 100 x 100 mm

- Automatic lubrication system

- 5C - 40C

- 5.5 kW

- Automatic feeding with tension adjustment

- Knuckled and twisted edge

- Standard export wooden case

- 1-4 m (adjustable)

- 75 dB

Best Automatic Chain Link Fence Machine Trade Information

- 5 Set Per Day

- 60-70 Days

Product Description

| GI wire | Max 4 mm |

| PVC wire | Max 6 mm |

| Size | 8 feet |

| SS wire | Max 4 mm |

| Wire Type | GI / PVC / SS |

| Wire Diameter | Max 4 mm |

| Phase | 3 Phase |

| Machine Speed | 600-700 RPM |

| Size Of Mesh | Max 120 mm |

| Operation Mode | Automatic |

| Production Capacity | 2500-3000 Kg/Day |

| Power Consumption | 10 HP |

| Brand | Secure Fencing |

Advanced Automation and Efficient Output

This double wire automatic fence machine seamlessly produces woven chain link fencing with adjustable mesh sizes and widths, all managed via a user-friendly touch screen and PLC control system. The automatic feeding and edge treatments deliver fast, precise, and consistent results ideal for high-volume manufacturing.

Robust Design and Enhanced Safety

Built for industrial use, the machine promises stability and safety with emergency stop and overload protection systems, plus an automatic lubrication system to extend working life. Its rectangular base and high-torque motor provide consistent performance even during demanding operations.

Comprehensive After-Sales Support

Installation services are available on request to ensure smooth setup and operation. The machine comes equipped with in-line quality inspection, and mechanical drawings are provided. Its multi-language interface and standard export packaging make it suitable for global exporters and manufacturers.

FAQ's of Best Automatic Chain Link Fence Machine:

Q: How does the automatic chain link fence machine operate and what are its key automation features?

A: The machine features fully automatic operation, including automatic wire feeding with tension adjustment, PLC control, touch screen interface, auto edge locking, and automatic lubrication. These key features streamline the production process and reduce manual intervention.Q: What is the production capacity and how flexible is the machine in terms of mesh size and wire width?

A: The production speed ranges between 120-180 m2/hour with support for wire widths from 1 to 4 meters and mesh sizes adjustable from 25 x 25 mm to 100 x 100 mm, providing flexibility for various project requirements.Q: Where can this machine be installed, and is installation support provided?

A: The machine is suitable for factories and manufacturing facilities. Installation service is available upon request, ensuring you receive professional support tailored to your setup.Q: When is regular maintenance needed and how is it managed?

A: Routine maintenance is simplified by the integrated automatic lubrication system. The machine's design ensures minimal manual lubrication, though regular inspections to check for wear or component alignment are recommended to maintain peak performance.Q: What safety measures are incorporated into the machine's design?

A: Safety is prioritized with features like an emergency stop button and overload protection, ensuring operators' security during high-speed production cycles.Q: How easy is it to operate the machine for non-English speaking operators?

A: The machine offers a multi-language interface, making it straightforward to use for operators from various language backgrounds. Comprehensive manuals and control options support clear, accessible operation.Q: What are the primary benefits of choosing this chain link fence machine for manufacturers and exporters?

A: Manufacturers and exporters benefit from high-speed output, low noise operation, robust safety mechanisms, anti-corrosive finish, and modular design with in-line QC. The machine's versatility, reliability, and ease of export packaging streamline both production and logistics.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry